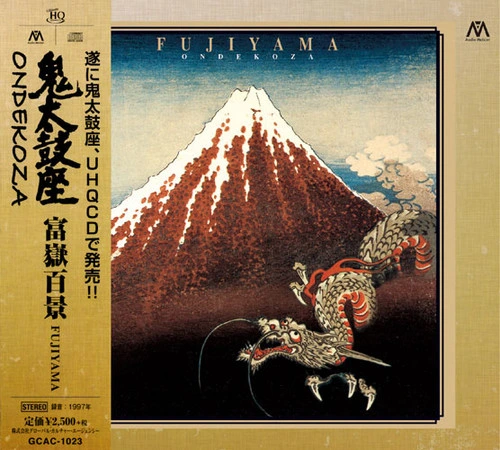

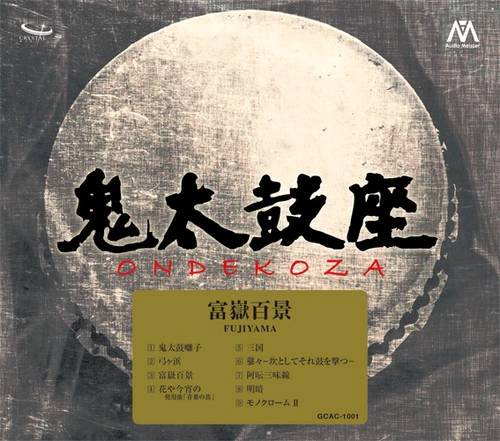

World renowned Japanese Taiko Drummers Ondekoza presented Japanese Import UHQCD!

World renowned Japanese Taiko Drummers Ondekoza presented Japanese Import UHQCD!Playable on any CD player, the Ultimate High Quality CD greatly surpasses all previous CDs before it!

In its forty-plus year history, Ondekoza has been influential in spreading and popularizing taiko, particularly outside of Japan. Many of pieces arranged by Ondekoza have been incorporated into the repertoire of taiko groups around the world.

Ondekoza continually pursues greater means of expression through the use of taiko drums. By trimming the performance of all that is excessive, and playing to the limit of physical capabilities, Ondekoza believes that the sound of the drum alone is capable of striking a powerful impression. Ondekoza aims to create stage pieces that are enjoyable to children and adults alike.

Before each show, individual shime drums are tightened to the limit- a task requiring the synchronized strength of two members- in order to achieve the cutting sound that is representative of Ondekoza's style.

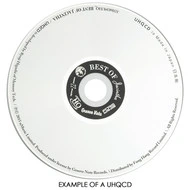

All About Ultimate High Quality CD (UHQCD):

Many years have passed since the birth of the Audio Compact Disc (CD) back in 1982. By use of High-Quality materials and a totally different manufacturing method, the definitive version of audiophile audio CD was born. Playable on any CD player, the Ultimate High Quality CD greatly surpasses all previous CDs before it!

The Ultimate High Quality CD (UHQCD):

UHQCD is a radical change to the CD manufacturing process itself. The conventional wisdom about CD manufacturing, which had remained largely unchanged across the world for over 30 years, has been exhaustively questioned. Through this effort, the ultimate in quality was attained - a level of quality that is certainly impossible to achieve with existing CD discs.

The Ultimate High Quality CD was developed through an effort to improve audio quality by simply upgrading the materials used in ordinary CDs to higher quality materials. For the substrate a high-transparency and high-fluidity polycarbonate (a type of plastic) of the type used for LCD panels was used, while for the reflective layer, low-cost, common aluminum was replaced with a unique and expensive alloy of high-reflectivity.

Differences in manufacturing methods:

Conventional CDs are produced using the technique of injection molding to form "pits" of data on polycarbonate material. Metal plate on which "pits" representing audio source data are formed is used as a die. This is called the "stamper." Polycarbonate is melted at high temperature and poured into the die to duplicate the pit patterns on the stamper.

This method is efficient because it enables high-speed production, but it does not enable totally accurate or complete duplication of the pits on the stamper. As a melted plastic, polycarbonate is inevitably viscous, so it cannot penetrate completely into every land and groove of the tiny pits of the stamper.

The Ultimate High Quality CD photopolymer is used instead of polycarbonate to replicate the pits of the stamper. In their normal state, photopolymers are liquids, but one of their characteristic properties is that they harden when exposed to light of certain wavelengths. The advantage of this property, perfect replication of very finely detailed pits was achieved. Photopolymers in the liquid state are able to penetrate into the tiniest corners of pits on the stamper so that the pattern of the pits is reproduced to an extremely high level of accuracy. The Ultimate High Quality CD reproduces audio with greater precision and at a level that is impossible to achieve using conventional CD production technology!

Packaged in an XRCD-like luxury digipak complete with full color CD booklet.

Features:

• Made in Japan

• Ultimate High Quality CD

• XRCD-Like Luxury Digipak

• Playable on conventional CD players

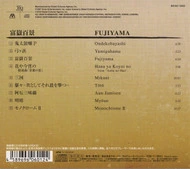

Selections:

1. Ondeko-bayashi

2. Yumigahama

3. Fujiyama

4. Hana ya kohoi no (from "Aoba no Hue")

5. Mikuini

6. Toto

7. Aun-Jamisen

8. Myoan

9. Monochrome II

Turntable Accessories

Turntable Accessories Headphone Accessories

Headphone Accessories Cable Accessories

Cable Accessories Vinyl Accessories

Vinyl Accessories Compact Disc Accessories

Compact Disc Accessories