The Walker Audio Extreme SST (Super Silver Treatment) Contact Enhancer is easily 20 to 30% better than the original! Legendary recording engineer Stan Ricker uses the Extreme SST (Super Silver Treatment) Contact Enhancer in his mastering system.

The Walker Audio Extreme SST (Super Silver Treatment) Contact Enhancer reveals sonic details and harmonics you’ve been missing! This kit comes with enough product to treat your system many times over and to share with your friends. Twelve applicators included!

Other Interesting and beneficial uses for the Walker Audio E-SST & SST Contact Enhancers! You gotta read this!!!

While developing E-SST – Super Silver Treatment, we tested many types of conducting substances and carrier fluids. We chose an ultra-pure, thin, long micron-sized silver flake suspended in an organic fluid for its dielectric characteristics and excellent sound. We believe E-SST are vastly superior compared to any contact treatment on the market today. Most contact treatments on the market are either cleaners or lubricants. They are not conductive. E-SST is highly conductive and must be applied with care according to directions.

Walker Audio Extreme SST (Super Silver Treatment) Contact Enhancer will dramatically improve the sound and/or video of any system. The highs will be more extended, cleaner, clearer and better focused. The mid-range will be more transparent with more articulation and detail, yet without harshness or glare. The bass will be stronger, tighter, and quicker. The soundstage will take on a more natural presence. With video systems, the sound improvement will be matched by the improvements to the video. Look for a cleaner, more three-dimensional picture.

Stan Ricker uses the Extreme SST in his mastering system! Stan is well known for his keen hearing and attention to details that some others do not understand. "The difference is in the details," says Stan. He has cut many highly regarded LPs for Mobile Fidelity Sound Lab, Crystal Clear, Telarc, Delos, Reference Recordings, Windham Hill, Stereophile, and roughly a dozen other labels, including recent work for Analogue Productions and AcousTech Mastering. He is currently the Owner/Engineer Of SRM.

CAUTION!!! Use at your own risk. Please read the instructions fully before proceeding. E-SST is highly conductive. If you bridge the gap between hot and ground with E-SST, you run the risk of damaging your system. Used as directed. E-SST can be removed by using a clean cotton swab or one of the unused applicators dipped in alcohol, fingernail polish remover, or contact cleaner.

Treating Interconnects:

Use one of the supplied applicators to apply a very small amount of E-SST to the male end of the interconnect. Spread it thinly on about ½ or ¾ of the length of the center pin. Apply E-SST to the outside only of the female end in a thin even coat. Now, plug in your interconnect and listen. On XLR interconnects, apply to male pins only. DO NOT put the applicator into the RCA or you will short it out.

Treating Power Cords:

Apply a thin even coat of E-SST to the male ends only. Cover both sides of the pins about half the length of the pins. On the I.E.C. male end at the component, do the same. Use only a very small amount. Do not over apply.

Treating Speaker Cables:

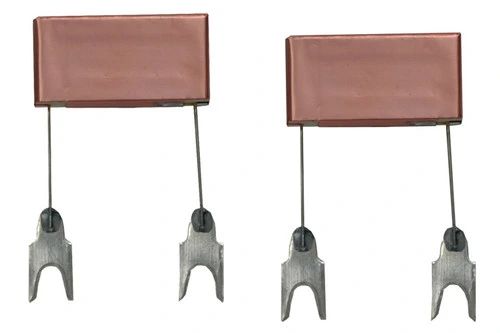

Apply a thin even coat of E-SST to the contact area of the spades or bananas.

Treating Tubes:

We experienced a big improvement when we applied E-SST to the pins of the tubes in our amplifiers. We suggest cleaning the pins with fine sandpaper in the direction on the pins. Clean with a contact cleaner, then apply a thin, even coat of E-SST to about 2/3 the length of the male pin.

Video/Other Uses:

E-SST works great on video connectors. Apply to the male pins and the outside of female connectors. SST also works on fuses and any contact device.

GUARANTEE

We offer a 30 day Guarantee of Satisfaction on the Walker Audio Extreme SST (Super Silver Treatment) Contact Enhancer.

HOW TO APPLY E-SST/SST:

1) Whether you are putting it on audio and video equipment or something else, the same rules apply. It is best to clean the connections with a contact cleaner that leaves no residue. If the contact is corroded, you can lightly sand or scrape it. Then clean it.

2) Apply a very thin (almost transparent) coat of E-SST to the male end of the connector. I’ve been asked which is the male end. For the uninitiated, the male end of a connector is the part that sticks out....think anatomy! Apply to the male end or to the ring connector or to the end of the spark plug that the plug wire goes to. Remember, very thin. More is not better.

REMOVE EXCESS:

If you get too much, use alcohol or contact cleaner to remove it. Take your time and pay close attention. Use E-SST at their own risk. E-SST is very conductive. If you get it across a connection, you can short out your equipment. When applied properly, you will have no problems. In fact, we guarantee you’ll be satisfied with the results or we will refund the purchase price.

IF PASTE GETS TOO THICK:

Over time, E-SST will dry to a thick paste. This is by design so that it does not migrate. In the bottle, if the E-SST thickens, simply add two or three drops of 100% canola oil available at any grocery store and mix with a toothpick. Canola oil has similar properties and will thicken over time, but will not effect the connection or the sound.

BREAK-IN PERIOD:

E-SST will immediately make a significant improvement. It will be even better after eight to ten hours of break-in time for the treated connectors.

RECONNECTING/REAPPLYING:

Before reconnecting, it is beneficial to take a used applicator with the E-SST wiped off (some will still be embedded in the applicator) and spread over the connector. This will help to distribute the E-SST that remains on the connector. If you reapply it, make sure there is not excessive E-SST on the connector. If there is, clean it as directed above before applying more. If you have any questions about how to use this product, call us.

NEW USES FOR SST:

Customers are applying E-SST to every electrical connection you could image. We thought putting it on a hair dryer was bit unusual, but my favorite is the customer who put it on his weed whacker. Lawnmowers and other outdoor equipment with engines can benefit from it. We've heard from our more adventurous customers, reviewers and manufacturers who have applied SST to the inside connections of projectors, computers, and DVD players and we've done this ourselves as well. The results are astounding. This is not recommended for most people, only for qualified electronic technicians. The inside connections are very small and close together and can be fragile. Use a bright light and magnifying glasses to see the connections and a sharp toothpick to apply E-SST. Use only a tiny amount on ¼ to ½ of the pin. And use extreme care to avoid damaging the connectors and/or shorting out your equipment.

Product Reviews:

"I think that 'Oh, S**t, why didn’t I think of that?' is and has been my immediate and longest-lasting impression of your SST... It’s so Self-Evident a super-logical way to increase the contact area of every connector in the Signal-Path!!! CONGRATS!! And what a difference!! It seems as though the Dynamic Contrasts of the music that goes thru my mastering system are now TOTALLY Original-Recording limited... not cutting-system related... especially the lowest-level tiny signals and the Impulse-type sounds like castanets and triangles... SST is on ALL Connectors thru-out my mastering system, and it sure does make a HELL OF A DIFFERENCE!!" - Stan Ricker

"Leave it to Lloyd (Walker Audio) to improve something you are happy with already"

"...don't upgrade components until you try this product first - it's that good." - Positive Feedback Online

"...you aren't really hearing what your system can do until you use it..." - Positive Feedback Online

"...it's one of those no-brainer inventions that even die-hard skeptics of all things tweak will embrace. The results are that obvious..." - 6moons.com

Turntable Accessories

Turntable Accessories Headphone Accessories

Headphone Accessories Cable Accessories

Cable Accessories Vinyl Accessories

Vinyl Accessories Compact Disc Accessories

Compact Disc Accessories